GREEN MÜNSTERLAND

Münsterland is the "Green Powerhouse" of North Rhine-Westphalia - a region where economic strength and ecological innovation go hand in hand. With its strong SME economic structure and a clear focus on sustainability, Münsterland offers ideal conditions for investments in renewable energies, the circular economy, clean tech and future-oriented business models.

The region's commitment to climate-friendly development is already clearly evident: 68% of electricity consumption in Münsterland is covered by renewable sources - significantly more than the national average. Some districts even exceed their own electricity requirements: Borken achieves a peak value of 106%, making it a net producer of green electricity. Coesfeld (75%), Steinfurt (73%) and Warendorf (61%) also record above-average figures.

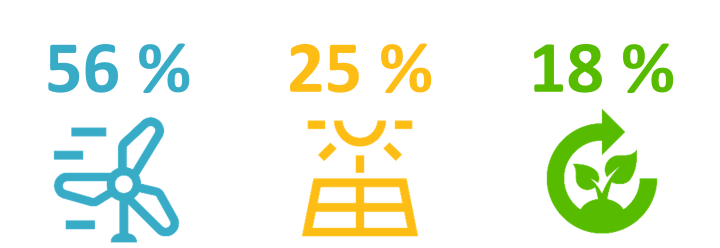

Generation is primarily based on wind power (56% of the renewable share), photovoltaics (25%) and biomass (18%). This diverse, regionally balanced energy mix ensures a stable, year-round supply and contributes to a resilient, decentralized energy infrastructure. For international companies, this means reliable access to carbon-neutral electricity, planning security for energy issues and an innovation-friendly environment for the green transformation.

BatteryCity Münster: Europe's hotspot for battery technology

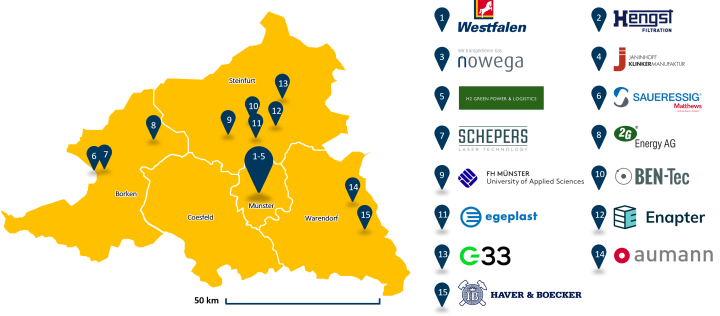

Münsterland is one of the leading regions in North Rhine-Westphalia in the field of battery systems - and is setting standards for Europe with BatteryCity Münster. Companies, research institutes and business-related institutions are pooling their expertise along the entire value chain in the battery systems cluster: from materials research and cell production to the development of intelligent energy storage solutions for mobility, industry and the energy sector.

Central players such as the Fraunhofer Research Facility for Battery Cell Production (FFB) the MEET Battery Research Center at the University of Münster, the Münster University of Applied Sciences and the Westphalian University of Applied Sciences. The cluster is supported by the Technologieförderung Münster GmbH which is responsible for coordination and works closely with business, science and politics.

The aim is to strategically position Münsterland as an international innovation and production location for battery technologies - particularly in the areas of electromobility, stationary storage solutions and decentralized energy concepts.

For international companies, Münster not only offers an excellent research and development infrastructure, but also direct access to green energy - for example through the region's first agri-PV plant, which supplies sustainable electricity for battery production. What's more, specialists, expertise and a practical network ensure short distances, clear processes and ideal conditions for investing in the battery technology of the future.

Münster is therefore the ideal location for companies looking to invest in the future of battery technology.

- Opened in 2009, moved to MEET-Arkaden in 2011

- Independent institution of the University of Münster since 2013

- >120 projects

- Research focus:

- Materials (active and inactive materials)

- Cell systems (cell & cell design, ageing, safety)

- Analytics & environment (material characterization, recycling & second life, method development)

- Founded in 2014 by FZ Jülich, the University of Münster and RWTH Aachen University

- Officially launched in 2015 as part of the Institute of Energy and Climate Research (IEK) at FZ Jülich (IEK-12/HI MS)

- New building directly next to MEET (launch in 2022, handover in 2025)

- Research focus:

- Solid-state, liquid, polymer and hybrid electrolytes

- InterfacesTheory & modeling

- Up to €820 million for building construction and equipment

- More than 200 battery experts (including partners)

- Innovation modules for start-ups and technology-oriented companies & projects

- Open battery factory for research into innovative production processes

- Electrode production (mixing, coating, drying, calendering, cutting)

- Cell assembly (winding, welding, housing, electrolyte filling)

- Forming (charging-discharging, ageing, degassing)

FFB Workspace - since 2011

- 430 m² incl. clean room

- 50 MWh/a (Electrode)

FFB PreFab - 2024

- 3,000 m²

- 200 MWh/a (Electrode)

FFB Fab - 2027

- 20,000 m²

- 6,8 GWh/a (Electrode)

- 3x200 MWh/a (Cell assembly)

Resources working group

- Circular economy and battery recycling

- Technical center since 2008 with an area of approx. 850 m²Laboratory and semi-industrial-scale trials

- Various shredding units for battery recycling

Research focus in the battery sector: Mechanical processing (shredding)

- Automation of the dismantling of LIBs and packs

- Sensor-supported processing of LIBs

- Wet processing methods

IWARU - Institute for Infrastructure · Water · Resources · Environment - FH Münster

Biomass Energy in Münsterland: Strong Agricultural Base, Smart Energy Solutions

As one of Germany’s leading biogas regions, Münsterland offers ideal conditions for investment in bioenergy. With more than 200 agricultural biogas plants and a total installed capacity of approximately 100 MW_el, the region stands out for its decentralized, flexible infrastructure and its innovative approach to renewable energy.

A key strength lies in the region’s agricultural structure: high livestock density provides large volumes of slurry and manure, forming a sustainable basis for biogas production. These are complemented by plant residues and energy crops like maize or grain. The focus is increasingly shifting toward environmentally sound, resource-efficient substrates.

Many of the biogas plants are medium-sized (250–500 kW_el) and operate in combination with CHP units to supply both electricity and heat. In addition, processed biogas is injected into the dense local gas grid as biomethane—enabling flexible energy use and integration into broader energy systems.

The region is also advancing biogas innovation. Research institutions such as FH Münster and the NRW Chamber of Agriculture are driving the future of biogas technology. Projects like VeBiT MSL and networks with universities support the development of modern fermentation techniques and circular resource use.

A best-practice example: the Bioenergy Park Saerbeck. Covering 90 hectares, the park brings together biogas, wind, and solar power—demonstrating how integrated, decentralized energy systems can succeed at scale.

Münsterland combines agricultural tradition with technological innovation—an attractive environment for investors in bioenergy and green infrastructure.

Hydrogen Region Münsterland: Infrastructure, Innovation, and Scalable Use

Münsterland is rapidly emerging as a key hydrogen region in Germany. From 2025, the region will be connected to the German hydrogen core network in the north, and by 2032, approximately 400 kilometers of pipeline infrastructure (300 km repurposed, 100 km newly built) will span the entire region. Additionally, a major hydrogen storage facility is taking shape in Gronau-Epe: by 2027, up to 66 million cubic meters of green hydrogen will be stored in salt caverns—ensuring long-term supply security and grid stability.

Infrastructure is only one side of the story—practical applications are already in motion. In Saerbeck, an integrated energy hub combines a megawatt-scale electrolyzer from Enapter and a hydrogen-powered CHP plant by 2G Energy. In Münster, Ziegelwerk Janinhoff has switched to green hydrogen for building materials production—demonstrating how carbon-intensive industries can decarbonize. Logistics firm L. Stroetmann operates hydrogen-powered trucks daily, and Warendorf District is preparing to deploy its first hydrogen bus for public transport.

Smaller companies are also taking bold steps: in Metelen, a regional SME is developing a smart energy site that integrates hydrogen, renewables, and storage—enhancing self-sufficiency and grid resilience. Steinfurt District is a recognized hydrogen mobility model in North Rhine-Westphalia, led by the “Green Hydrogen Mobilizes energieland2050” initiative and the HYMAT Energy Competence Center.

On a European level, Münsterland plays a key role in H2EART, the first cross-border Hydrogen Valley in Northwestern Europe. With more than €500 million in total investment and 58 partners across 10 countries, this initiative connects global ambition with strong regional roots—placing Münsterland at the heart of hydrogen innovation.

Circular economy

With the "Circular Economy Region Münsterland" initiative, Münsterland e.V. and its partners have established a strong network that supports companies in developing circular business models, closing material loops and tapping into new value creation potential. The focus is on circular construction, bio-based cycles and innovative packaging solutions, among other things.

Numerous companies, research facilities and institutions are contributing their expertise to regional projects and making Münsterland a future-oriented location for the circular economy. This opens up attractive cooperation opportunities for investors - especially at the interface of sustainability, technology and production.

Further information on the initiative: Circular Economy Region Münsterland | Competence Network